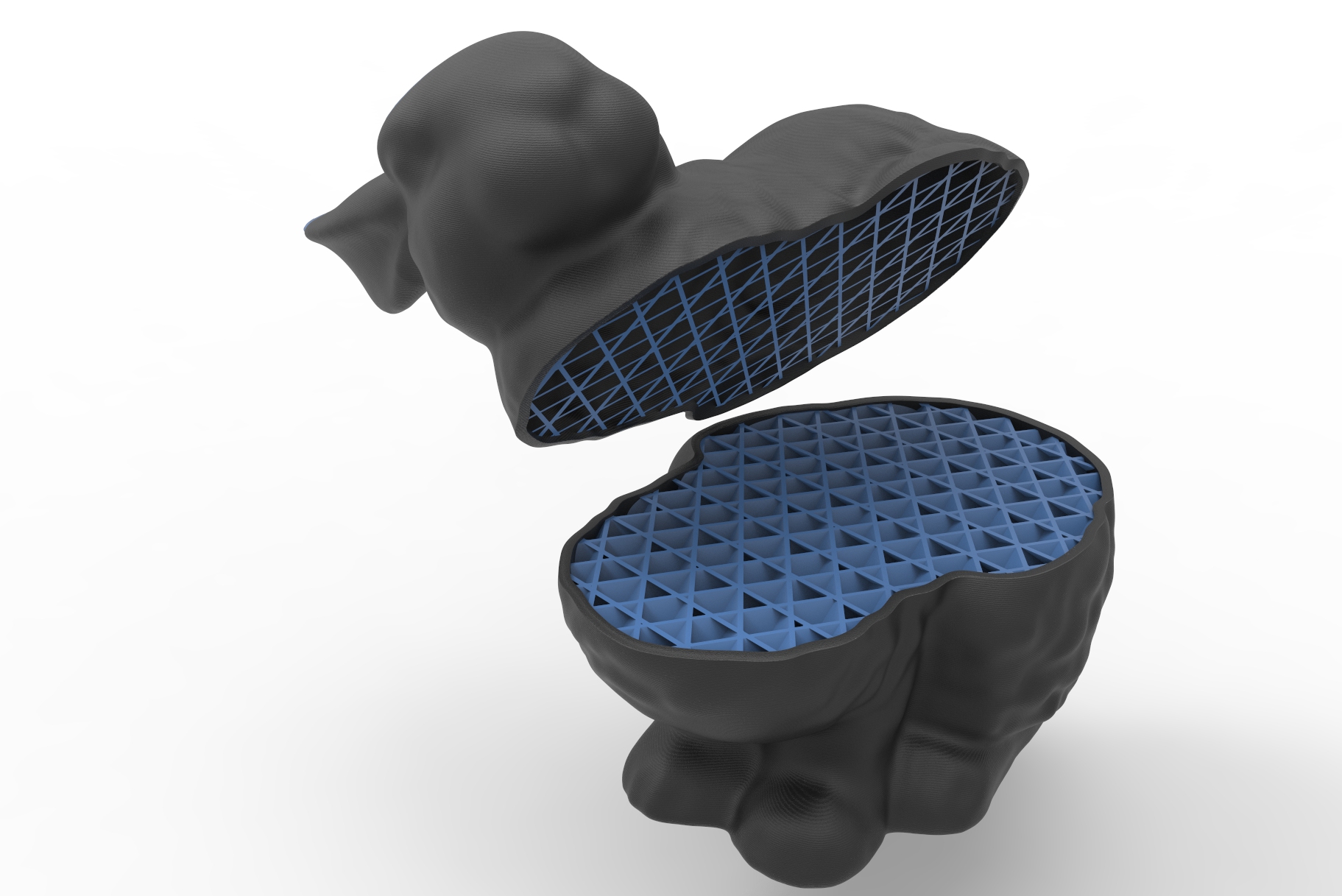

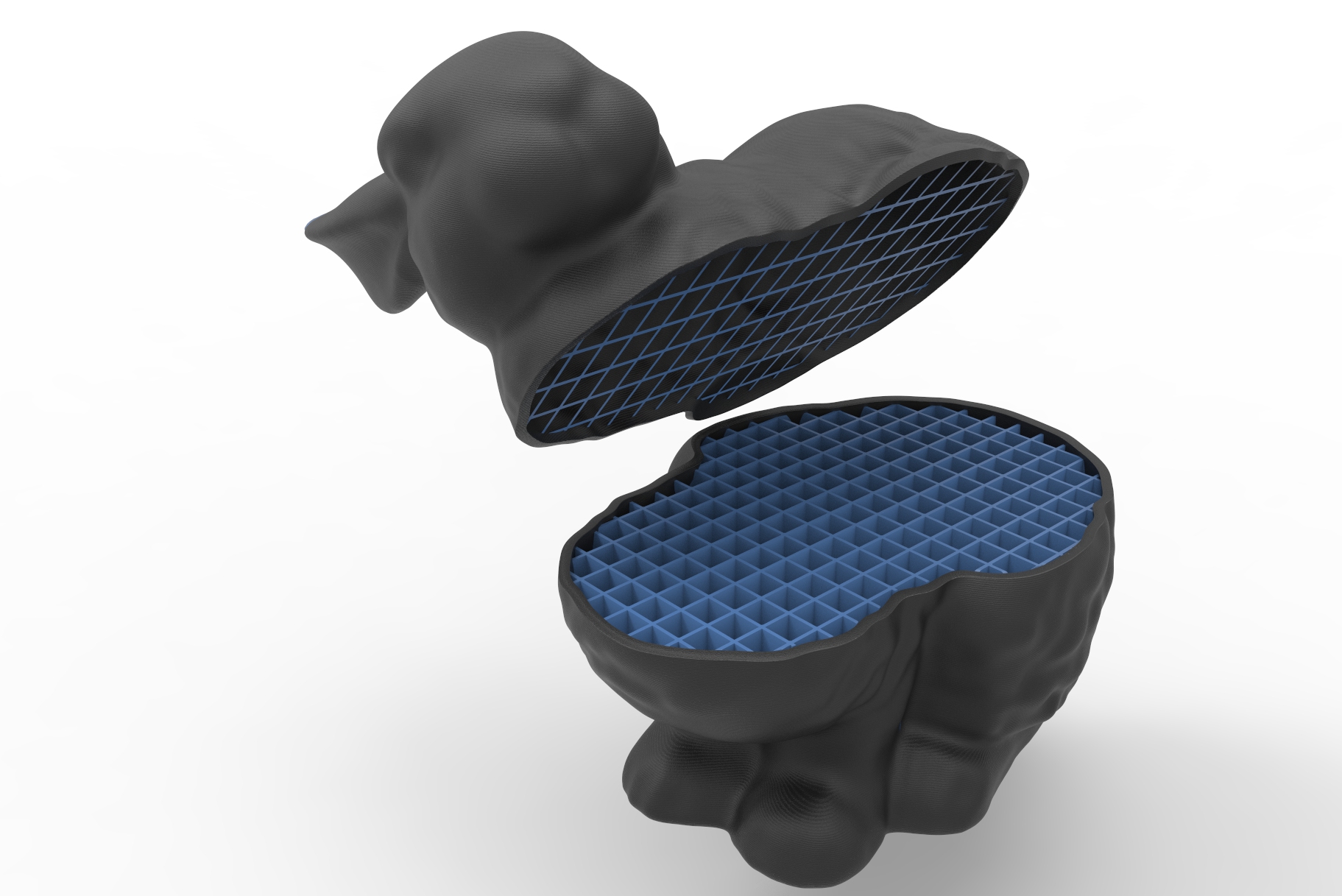

Absolute Infill and Cubic Infill

Project Description

In the 3D printing industry, a slicing engine is used to prepare 3D models for 3D printing. The industry standard method of printing defines the internal structure of the printed object as a function of density, which unfortunately can be affected by printing parameters rather than the designer’s intent. Furthermore, there is usually only one kind of 2D internal structure pattern used for 3D printing. This internal structure pattern is hollow along one axis, creating objects significantly weaker in one plane. I challenged these imperfect years-old industry practices and created and advocated for the industry-first Absolute Infill and Cubic Infill paradigms.

My feature, Absolute Infill allows the user to specify the separation length between each infill line, allowing for reproducibility of 3D printed parts. Cubic Infill allows the user to print 3D objects with a lattice of cubic internal structures, ensuring that the object is equally strong in all directions. Using these features, an engineer can communicate his/her design intent without ambiguity.

I took these steps to complete the features:

Promoting Absolute Infill and Cubic Infill was challenging as I had to advocate against the old method of defining infill and risk alienating our users. To mitigate this problem, I worked closely with the marketing department in the launch and wrote white papers and blog posts to explain how Absolute Infill and Cubic Infill address major 3D printing problems. I worked with the software engineer to package the software and add in functionality so that users could visualize the infill and get a better mental image of what they were doing.

Skills

- C++

- Python