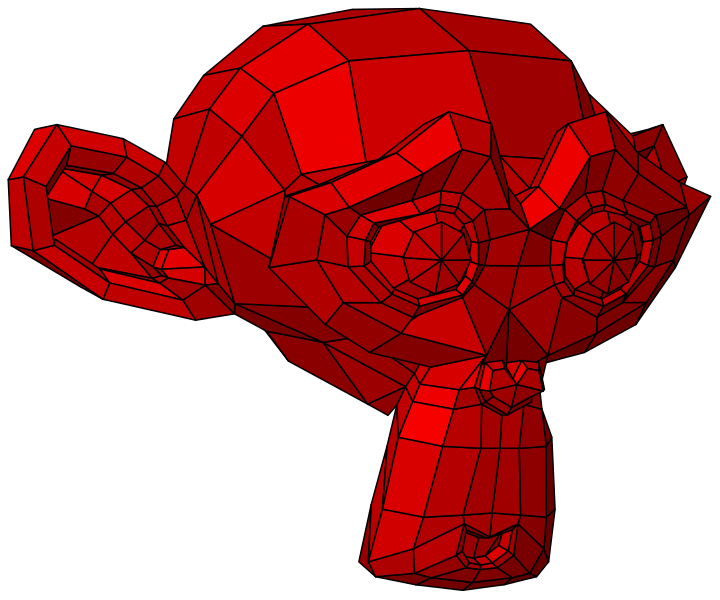

Design Space Visualization

Project Description

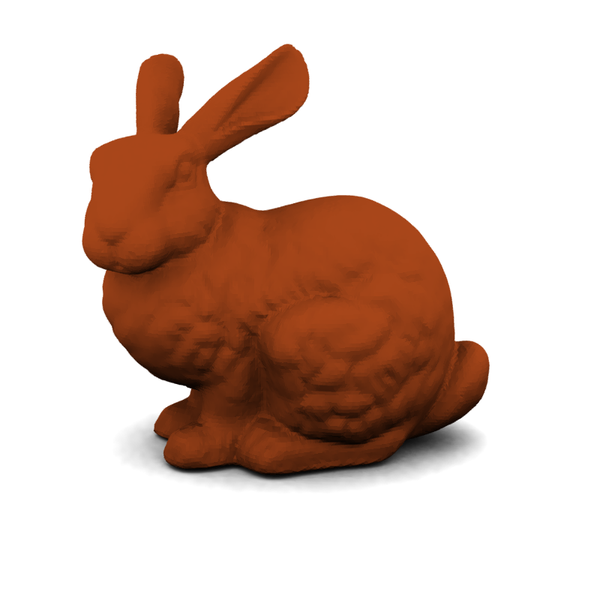

Broadly, in 3D printing there are 3 types of constraints determining the print time: those imposed by the 3D object, the 3D printer and the material. The general expectation is to reduce printing time yet no software considers the constraints imposed by the 3D object in the printing process. I developed a software feature that conducts model-based optimization and presents the user with a series of solutions such that he/she can make an informed decision based on their print time preferences.

This feature is special because it paves the way for intelligent 3D printing software that can make print setting recommendations based on model geometry. In initial testing, it has proven to save hundreds of hours of 3D printing time during mass production with 3D printers.

I took these steps to complete the feature:

If you are interested in learning more about this project please contact me at mail@vaibhav-sharma.com and I'd be happy to talk about it.

Skill

- Python; Numpy, Scipy, Matplotlib

- 3D printing

- Optimization in engineering design

- Design of experiments