Optimization of 3D Printing Parameters

Project Description

Originally at Type A Machines, 3D printing parameters were usually developed by trial and error. As an intern, I aimed to improve and formalize the development of 3D printing parameters. I applied the concepts of engineering optimization that I learned in graduate school to develop methodical techniques for developing printing profiles. Since then, I have built other automated techniques for testing which have also validated the results of my optimization method.

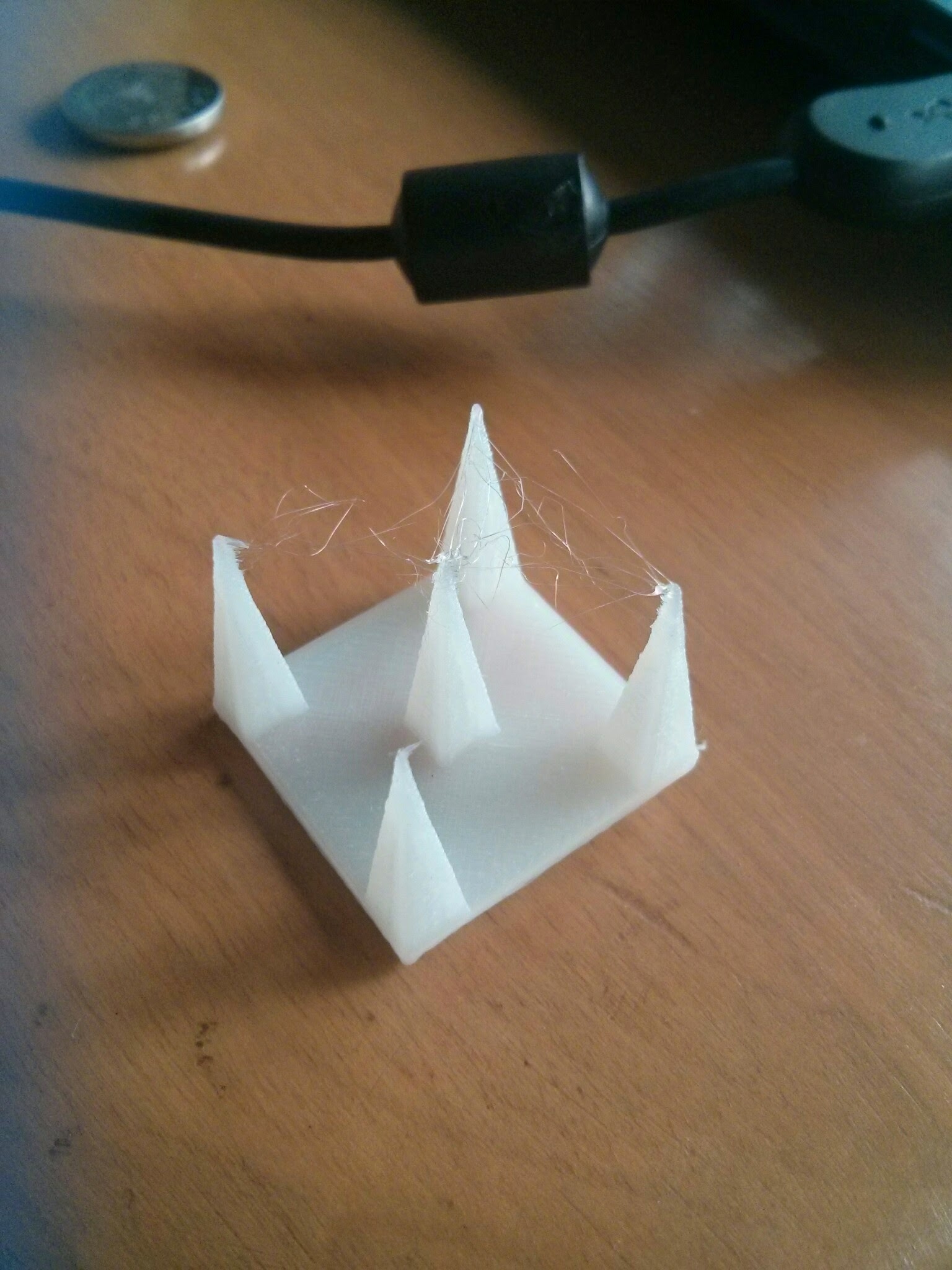

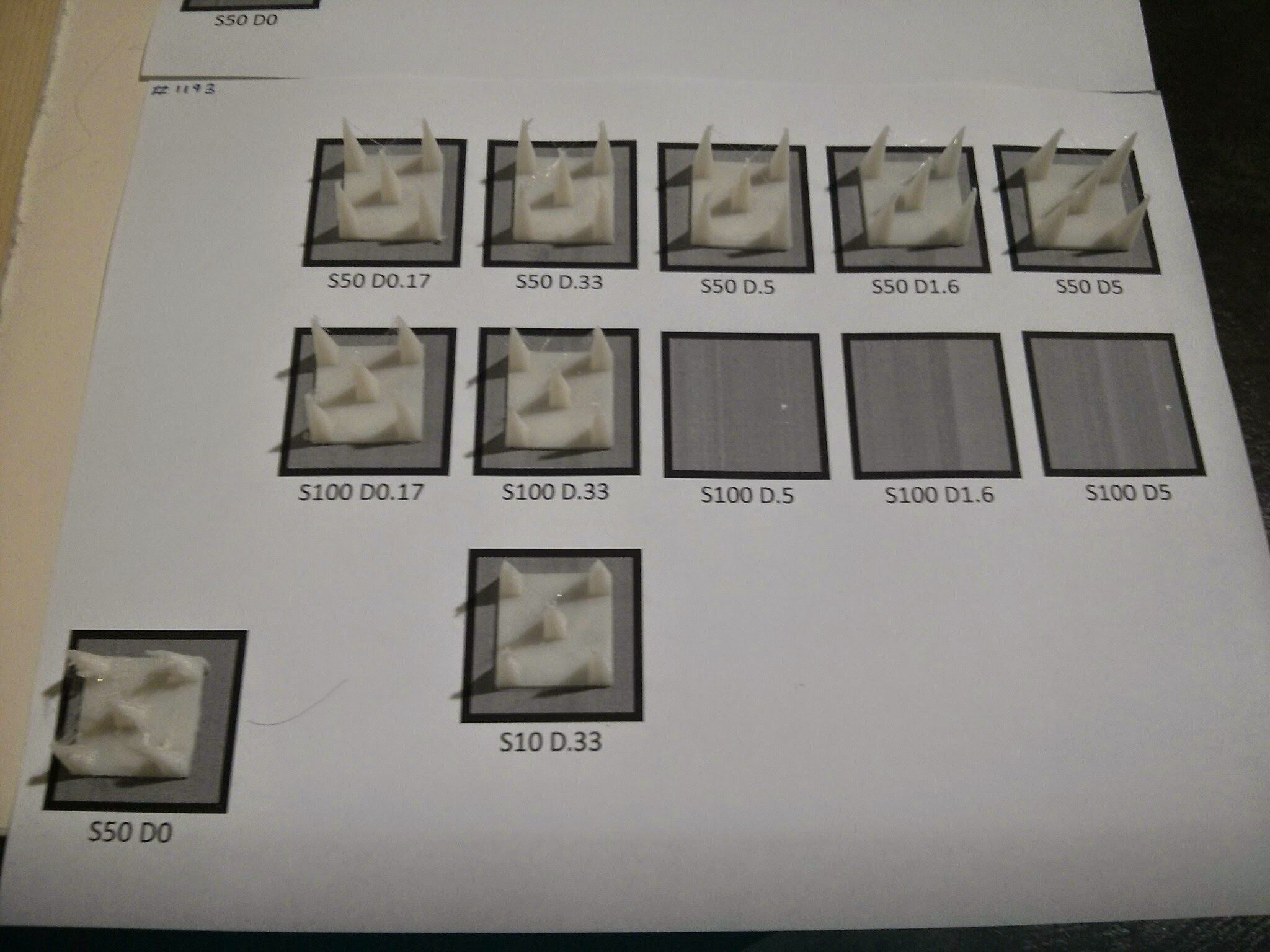

Using the process I developed, one could iteratively test and develop 3D printing parameters without any prior knowledge of the process. To illustrate this method, I chose two variables: retraction speed and retraction distance. I designed an experiment to iteratively traverse and optimize in the design space. I used a golden section search method to converge at a solution that provided the optimal retraction speed and distance.

This was one of my favorite projects as an intern at Type A Machines because I was able to apply academic concepts to a real world problem. The results I obtained paved the path for more methodical testing in the company and eliminated the earlier brute force approach.

Skills

- Optimization in engineering design

- Design of experiments (DOE)

- 3D Printing